This series of lectures focuses on Reduced Oxygen Packaging (ROP), which are used by food processers to help extend the shelf life of products. These packaging technologies (e.g. vacuum packaging) offer many benefits; however not without serious food safety risks. Understanding how to control these risks and comply with the Nebraska Food Code are key to a safe product when using this type of packaging.

Overview of Reduced Oxygen Packaging

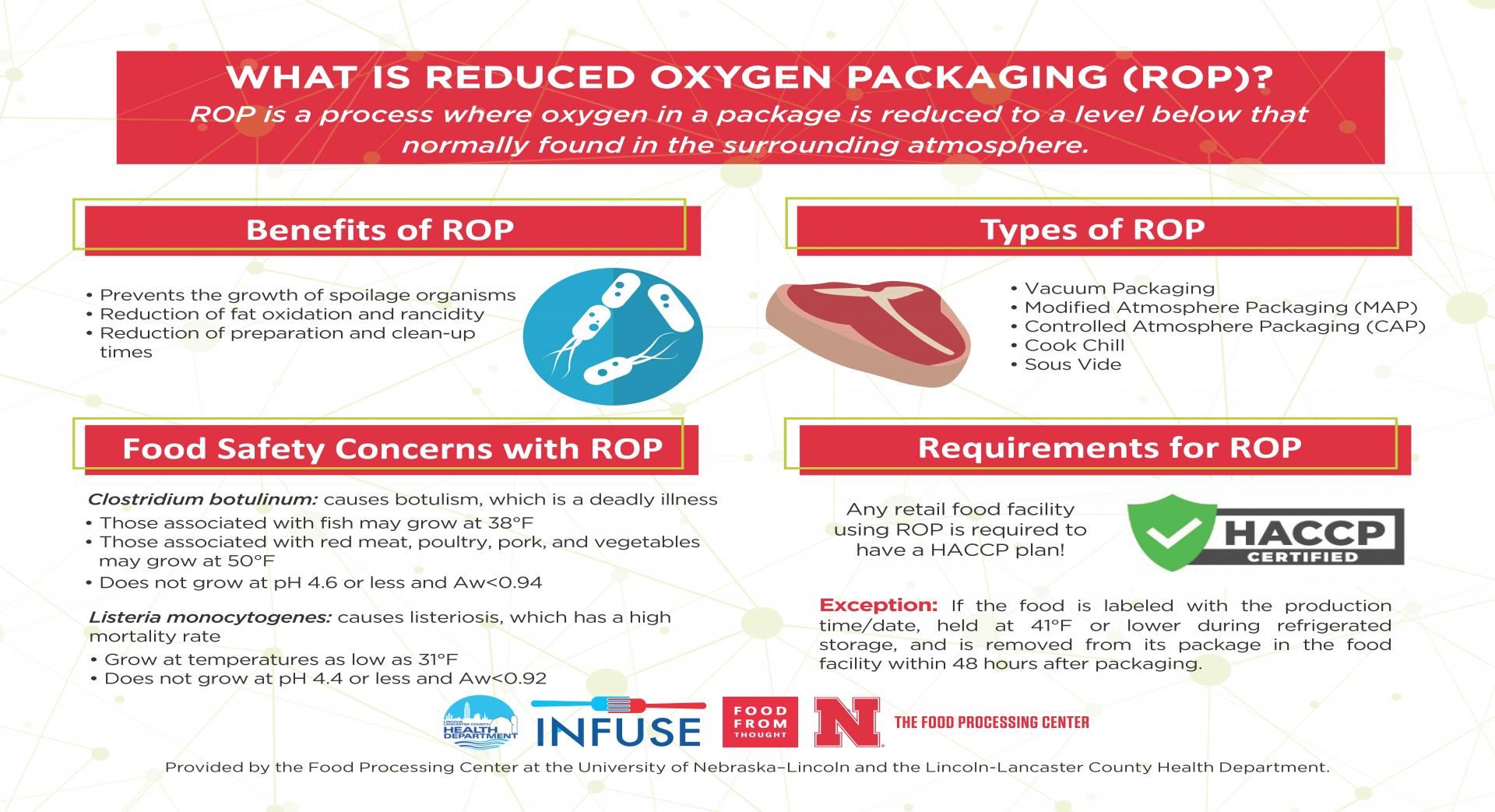

In this lecture an overview of Reduced Oxygen Packaging is provided, along with some definitions, risks and misconceptions associated with this process.

Overview of Reduced Oxygen PackagingTypes of Reduced Oxygen Packaging

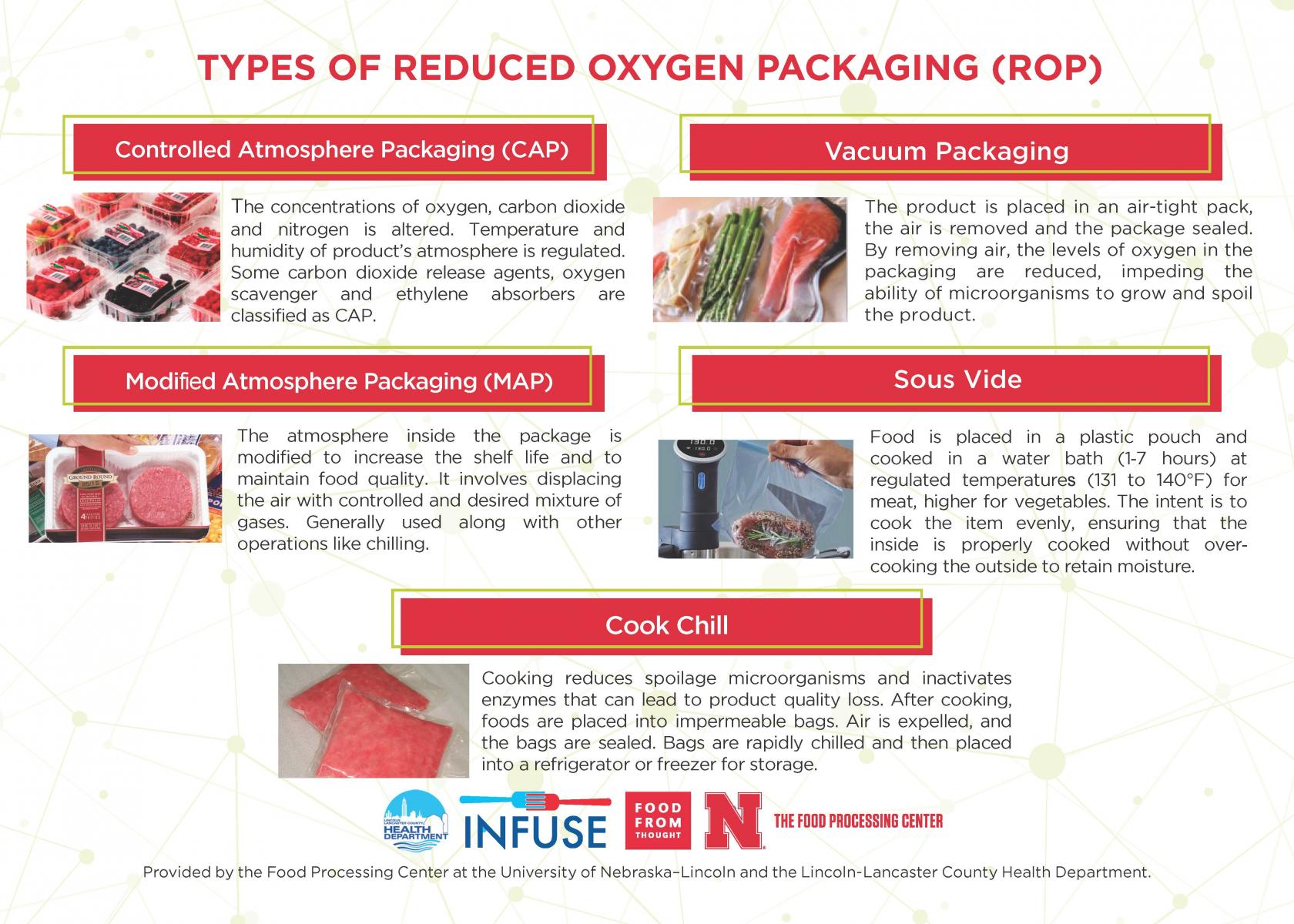

This lecture covers the different types of Reduced Oxygen Packaging, including vacuum packaging, modified atmosphere packaging, controlled atmosphere packaging, cook/chill process, and sous vide process.

Types of Reduced Oxygen PackagingSafety Concerns Associated with Reduced Oxygen Packaging

Here an overview of food microbiology is provided. It starts by describing the different groups of microorganisms associated with food, such as molds, yeasts, and bacteria. It then focuses on bacterial reproduction, spore formation and the factors that affect bacterial growth and survival. The last part of this lecture focuses on bacterial pathogens associated with food, the disease they cause and processing factors that may be used to control them in reduced oxygen packaged foods.

Intro to MicrobiologySanitation

This lecture describes the importance of sanitation in food retail environments and restaurants and provides some basic knowledge in this area. Some of the topics discussed include proper cleaning prior to sanitation, chlorination basics and factors affecting the efficacy of chlorination, other sanitizers than chlorine, and some practices to prevent contamination and cross-contamination in the food preparation environment.

SanitationRegulatory Requirements Associated with Reduced Oxygen Packaging

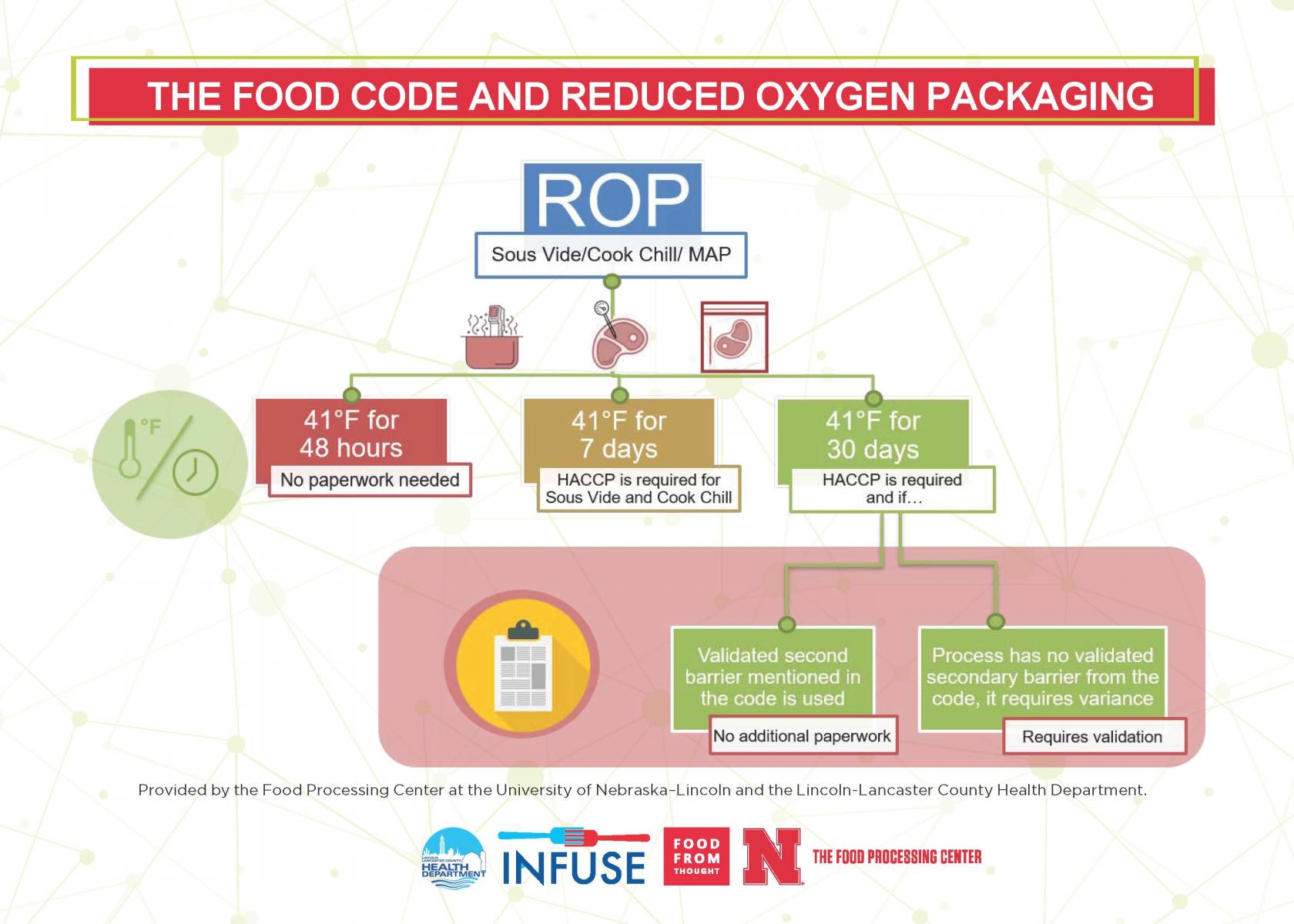

In this lecture requirements associated with state and local regulations are described for reduced oxygen packaging. Included are also some examples of how to meet those regulations, such as when variances are required and temperature/time controls for different food products.

Regulatory RequirementsDownloadable Cards

Questions? Please contact the Food Processing Center at fpc@unl.edu